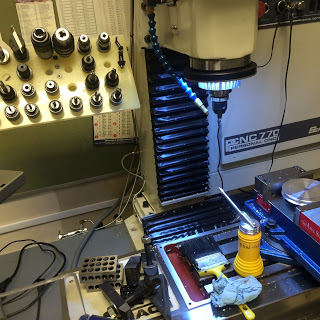

A couple of weeks ago, we received a grant from the Ball Brother Foundation. With this grant we purchased a CNC Mill.

After talking with Mike Koch a head mentor here at PhyXTGears, I began to have a better understanding of what exactly a CNC Mill does and how important it is that we have one now. We have a regular mill here in our machine room, it can cut on three different dimensions/axis’ (x-axis, y-axis, and z-axis). And although it has been useful so far, you can only cut on one axis at a time and even then, it may not come out as perfectly as you need it to. Mike described it as an Etch a Sketch, if you grew up using those fun toys you know that you can create some pretty cool stuff, but it’s going to come out with squiggly and choppy lines sometimes.

So here is the cool news about the CNC Mill, it has four different dimensions and axis’ that you can program it to cut on. ( the x, y, z, and a-axis). They can all be working at the same time to cut away the material you put in. This machine will easily “Make parts that can’t be made by man.” says Mike. It can make intricate designs out of metal, it can make parts and edges just the way you need them to be with ease. No choppy edges or squiggly lines. Everything is just as smooth and exact as you need it to be.

We can’t thank the Ball Brother Foundation enough for their generous grant, and we can’t wait to see the full extent of everything we can accomplish here with the CNC Mill.

|

| Setting up the new CNC Mill |